Brief introduction of advantages

Universal control valve

Whether under high pressure, in corrosive media, or in sub-zero fluids, the plug valve series is designed with low torque to reliably meet most requirements with low energy consumption.

Heavy duty control valve

Highly engineered anti-cavitation control valves eliminate harmful wear, which can extend service life and reduce cost of ownership. Multiple material, pressure and temperature options maximize flexibility for demanding service applications.

Ball valve

Long service life in harsh applications including corrosive fluids and refrigerants, ball valves can be customized according to international design and performance standards.

Butterfly valve

Low friction and torque, bi-directional sealing, inherently fire-resistant construction and no-blind zone design provide superior performance and long-term value, ideal for precise throttling and switching applications.

SRD998

More aerodynamic performance options are available, including high flow versions, while providing up to 10 bar of supply and output pressure. The high output pressure allows the positioner to operate at higher torques on actuators and valves; Therefore, smaller actuator sizes can be used. Because the high-flow version of the supercharger does not need to be small, it helps to save money.

Robust and reliable design

Easy to use user interface

Modular Optional option

Equipped with basic/advanced diagnostic functions

SRD960 / SRD991

Offering the most advanced technology available on the market today. These include an infrared interface for wireless operation and configuration, a multilingual full-text graphics LCD, and a full selection of all communication protocols for process automation applications. It provides enhanced applications and methods to analyze recorded trip data. The locator DTM(VALcare) makes it easy to configure and display all diagnostic functions. The Positioner DTM edits a complete "Health" report of the valve based on all configuration and diagnostic data. It also has the ability to control partial stroke testing (PST), which provides the operator with the ability to identify the troubleshooting function of the ESD(emergency shutdown) valve.

Predictive maintenance capability

Intelligent alarm management

Self-monitoring in compliance with NE107

Service management

Bar chart of valve position and response history collects data for up to 60 months

Data is stored in the positioner memory to determine stem friction to prevent leaks and a bar chart of rod friction history

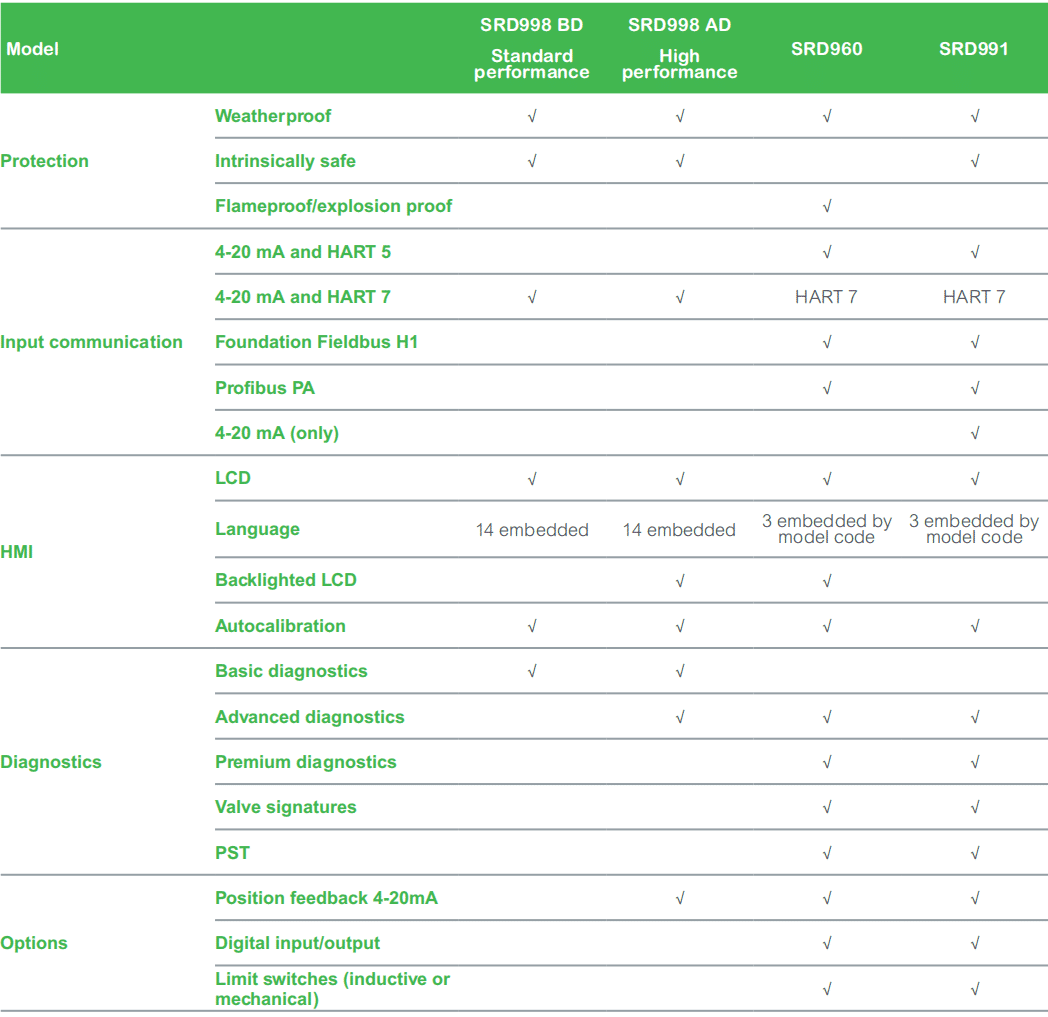

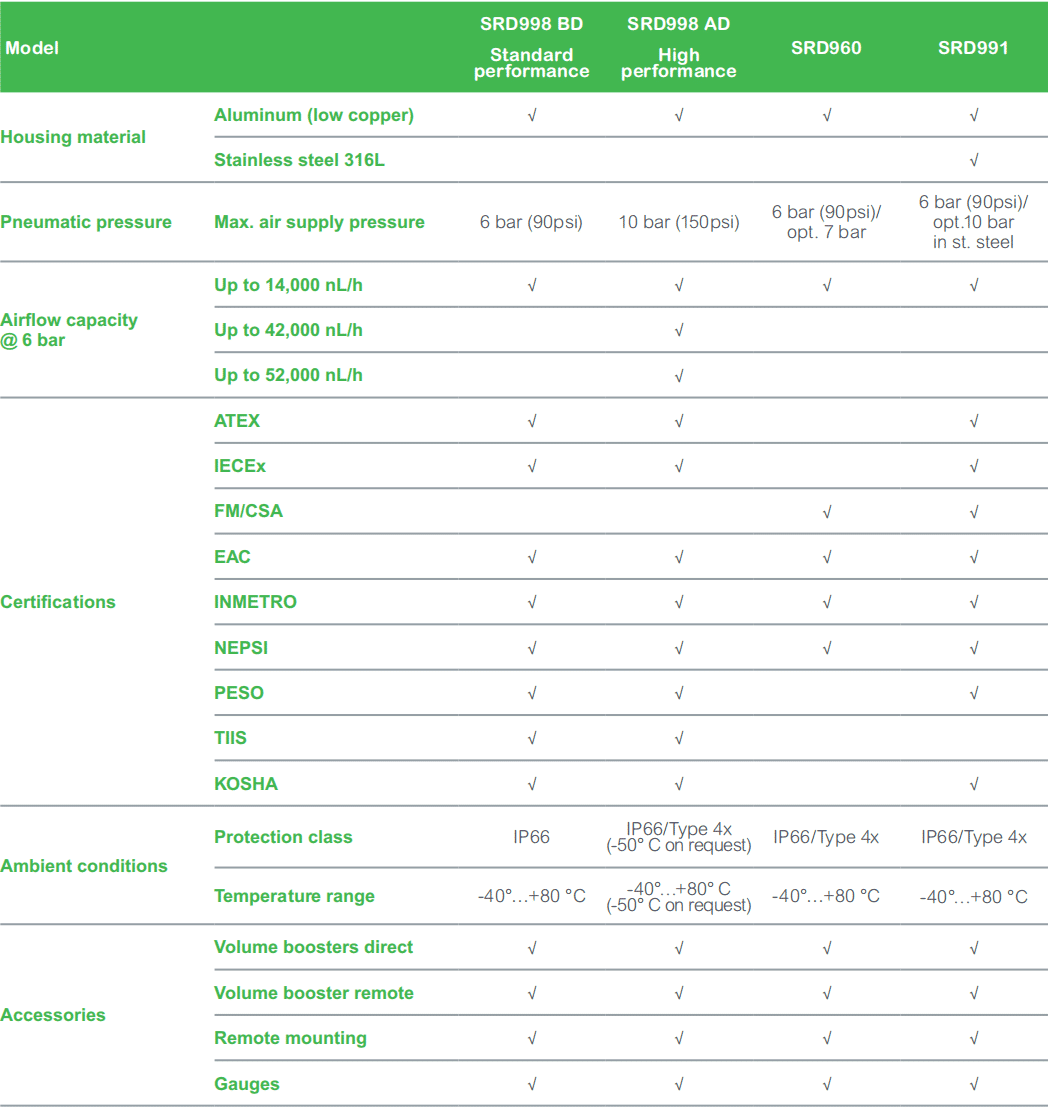

Selection guide

Partial Stroke Test (PST) applications with solenoid valve (SOV) monitoring provide high security against false trips and SOV error testing.