Brief introduction of advantages

Designed based on extensive industry experience for robustness and reliability

Patented FoxCal technology

High accuracy (percentage of degrees)

400:1 range ratio

Fast response

TUV safety certification

The latest communication protocol products

Predictive maintenance

FoxCal™ :Multiple calibration technique

In contrast to the static calibration method used by traditional suppliers and the traditional two-point calibration technology, Schneider Electric invented the FoxCal dynamic technology, which embeds 11 calibration curves in a single pressure transmitter. These 11 calibration curves are permanently stored in the sensor memory. Pressure transmitters with FoxCal can automatically switch to the optimal calibration curve based on the transmitter input.

Improved process accuracy thanks to FoxCal technology, the pressure transmitter in the measurement range of 100% to 4% of the upper limit (URL), its reading accuracy (% ofreading) is high and remains unchanged.

Reduce inventory costs

Improved range ratios and fewer sensor range options can have a significant impact on inventory. Pressure transmitters using FoxCa technology can reduce inventory by two-thirds, which would normally require the use of multiple different transmitters, but now only one is needed, which means fewer spare parts and reduced inventory.

Expedited maintenance operations

Zero-based range transmitters no longer require application-specific factory and field calibration. This significantly improves field replacement speeds and saves valuable time in maintenance operations.

Wide range for easy sensor selection

FoxCal technology makes the choice of sensor range very easy. Due to the wide range of reference accuracy and the automatic switching to the most suitable calibration curve, pressure transmitters with FoxCal dynamic technology can cover 3-4 ranges of traditional pressure transmitters. This wide range and high precision product helps to standardize a single pressure transmitter, thereby avoiding misselection of the sensor range

The Schneider Electric Advanced and Premium series pressure transmitters maintain the reading accuracy of the percentage between 100% and 4% of the upper limit (URL) of the measuring range. The accuracy of conventional pressure transmitters begins to decline at a higher percentage.

Both device security and availability

For Schneider Electric pressure transmitters, safety is standard, not optional! In addition to the traditional institutional certification, these pressure transmitters are certified to the TUV SIL2/SIL3 standard. The same transmitter can be used in both standard and safety applications. To identify pressure transmitters designed for safety circuits, you can order pressure transmitters with red or yellow caps. According to IEC61508, Schneider Electric pressure transmitters can be used in the SIL2 safety function of 1001 single mode or in the SIL3 safety function of 1002 dual mode.

Easy integration into the system

To ensure easy integration into the system, Schneider Electric pressure transmitters and associated configuration files have been tested in a dedicated interoperability laboratory. Schneider Electric pressure transmitters offer analog and digital communication protocols such as HART/4-20 mA, Foundation Fieldbus (FF), low-power versions (1 to 5 VDC) and Modbus. For further expansion, our pressure transmitters have become compatible with field device interface technology.

Improved maintenance diagnostics

To speed up maintenance start-up, the latest version of the digital communication protocol has been optimized for embedded diagnostics. In addition, two clocks are integrated: one for tracking the number of days the pressure transmitter is in use on site, and the other for planning maintenance operations. This is a key parameter for predictive maintenance.

Electrical safety classification

Schneider Electric pressure transmitters can adopt specific requirements specified in any of the various agency certifications. These include intrinsic safety, non-flammability, explosion protection and fire protection ratings for departments and regions. Certification in accordance with FM, CSA, IECEx, ATEX requirements as well as local certification (INMETRO, EAC, NEPSI, KC, etc.) Schneider Electric pressure transmitters are subject to multiple certifications for individual products, as well as TUV SIL2/SIL3 standards, facilitating product selection, quick replacement and optimized inventory for customers worldwide.

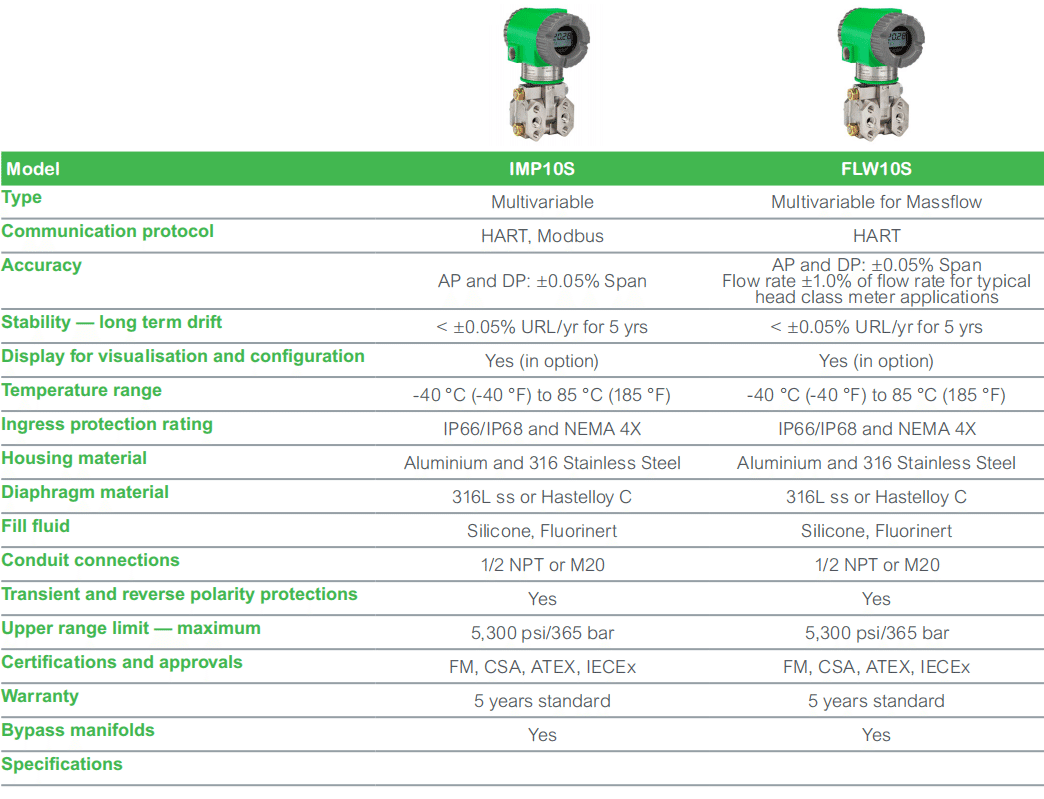

A multivariable transmitter that can measure three values

Multivariable transmitters measure absolute and differential pressures, temperature of sensors and electronics, and process temperature (from external RTDS). Three dedicated instruments (differential pressure, absolute pressure and temperature pressure transmitters) can be replaced with a single device that can measure multiple values and calculate flow. Multivariable transmitters can typically reduce the cost of mass flow installation by about 40%. In addition to minimizing the number of devices, this is due to less process penetration, fewer shutoff valves, less wiring, and fewer I/O modules (which transmit measurement data to a centralized system). All of this helps to significantly reduce installation time and further reduce costs, without compromising reliability and measurement accuracy. In addition, the DTM(Device Type Manager) file provides convenient configuration of the pressure transmitter, which is easy to configure and requires no special software.

Improve accuracy

Installing only one meter minimizes the impact on flow as well as any negative impact on measurement accuracy. Applying improved sensor technology and built-in computing capabilities, the pressure transmitter can compensate for any change in temperature, pressure, density or viscosity to provide accurate readings.

Selection guide

The FLW10S multi-variable flow pressure transmitter measures absolute pressure, differential pressure, process and transmitter temperature, and calculates mass flow. Full flow differential can be as low as 0.12kPa(0.5inH20 or 12mbar) and as high as 210 kPa(840 inH20 or 2.1 bar).

When systems employ multiple separate measurements to do monitoring, control or computation work, IMP10S is an ideal solution with HART or Modbus digital communication.

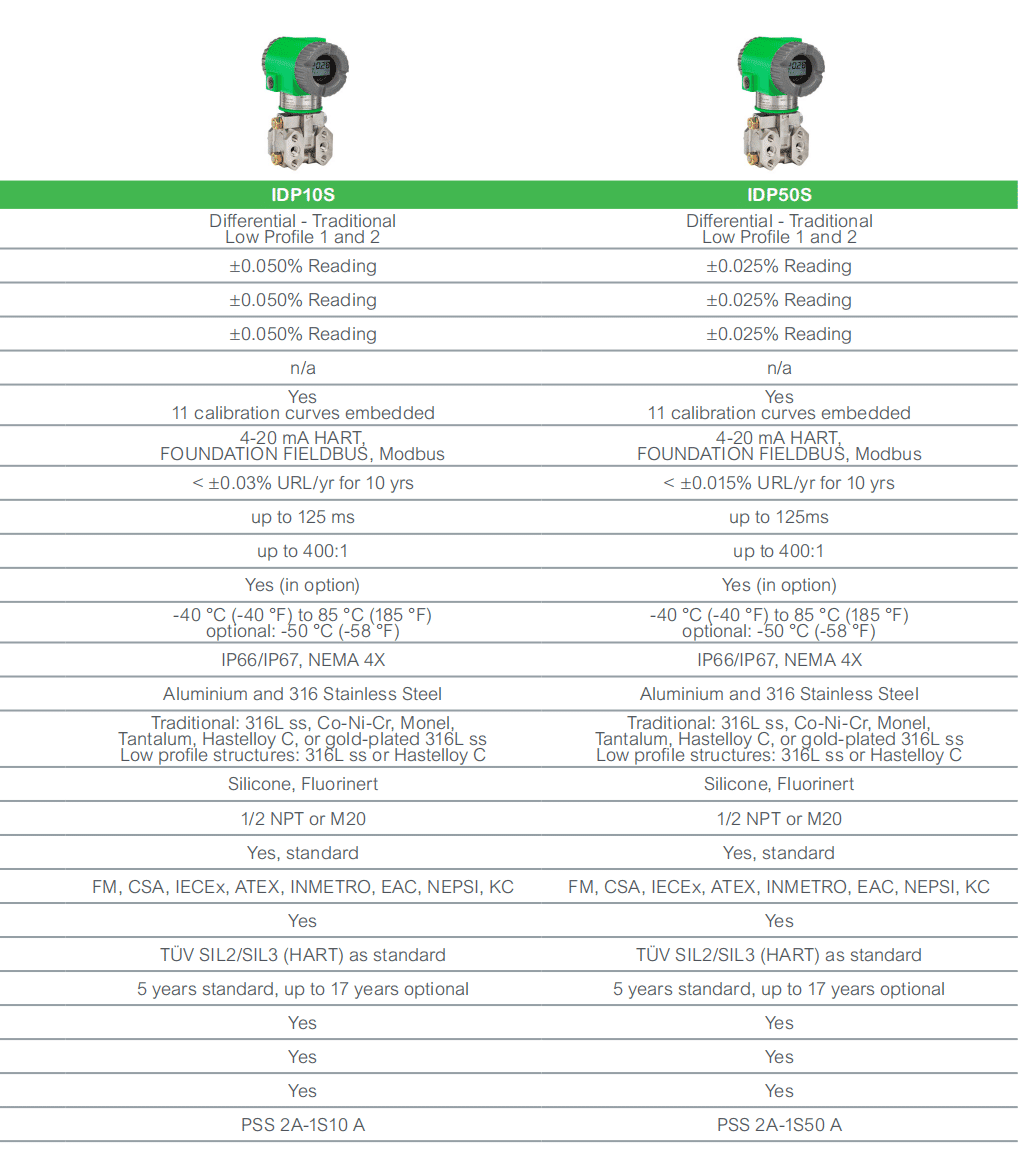

The Premium series of pressure transmitters, with FoxCal™ technology, is ideal for all challenges. For ten years, the stable reading accuracy of ±0.025% has been leading the industry and the stability is better than the annual URL of ±0.015%.

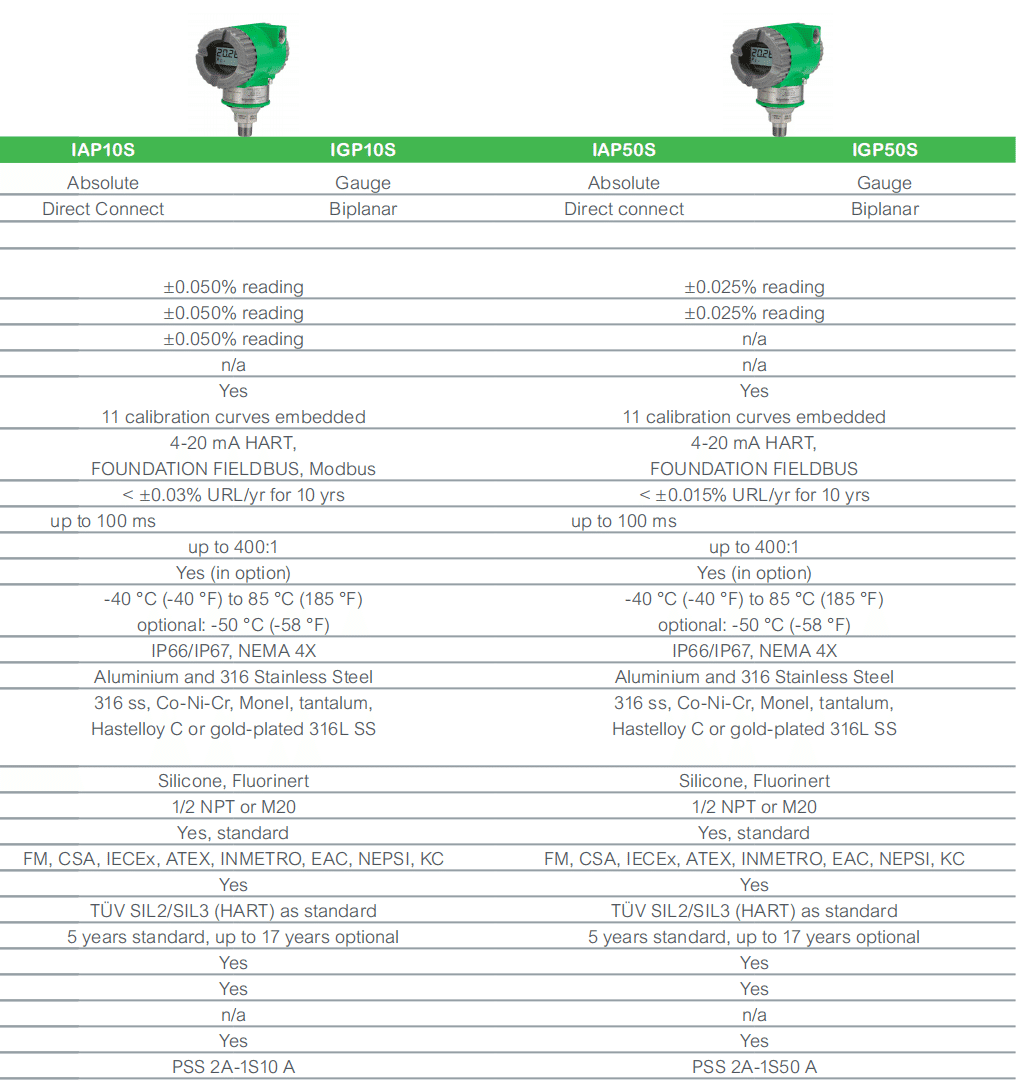

The Advanced series of pressure transmitters have a reading accuracy of +0.05%(URL from 100% to 4%), and the integrated FoxCal technology makes the choice of sensor range extremely simple.

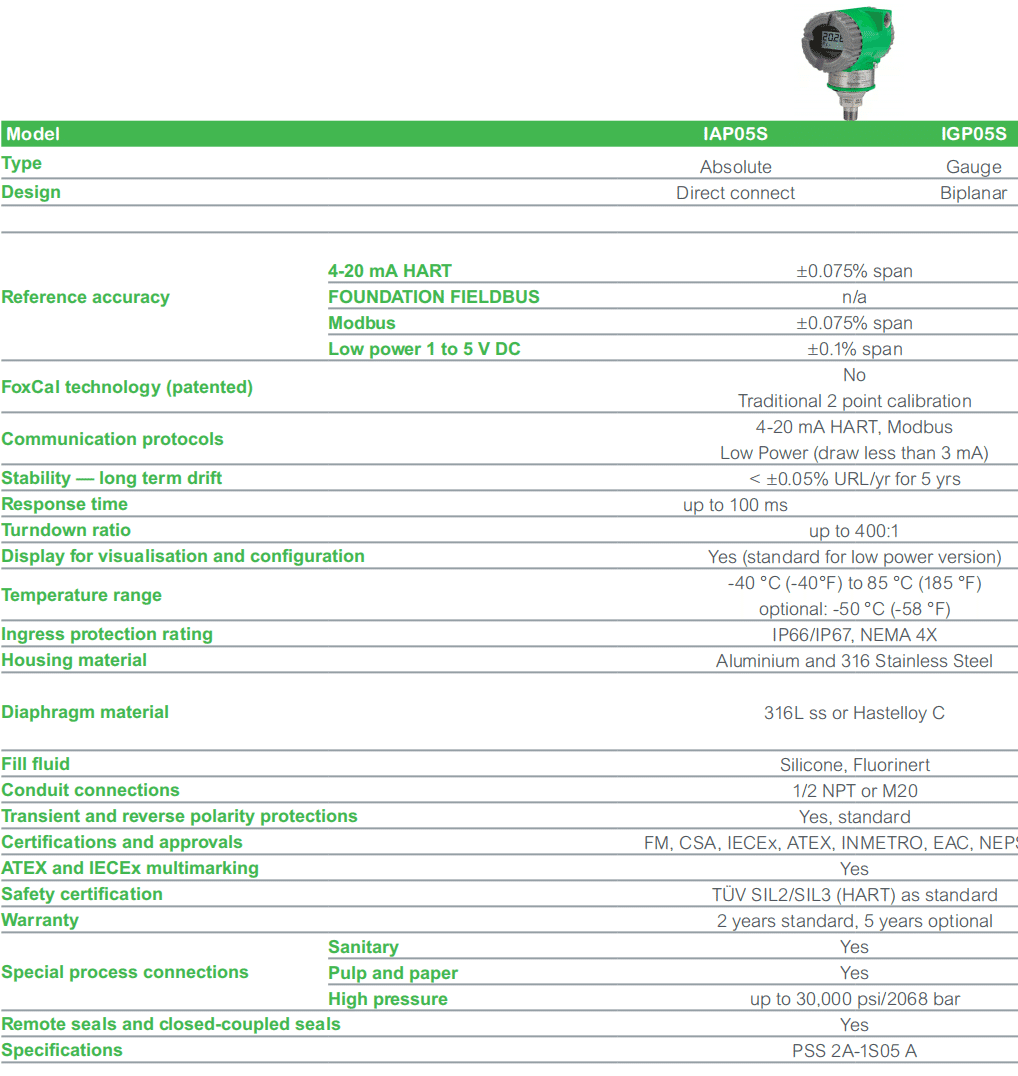

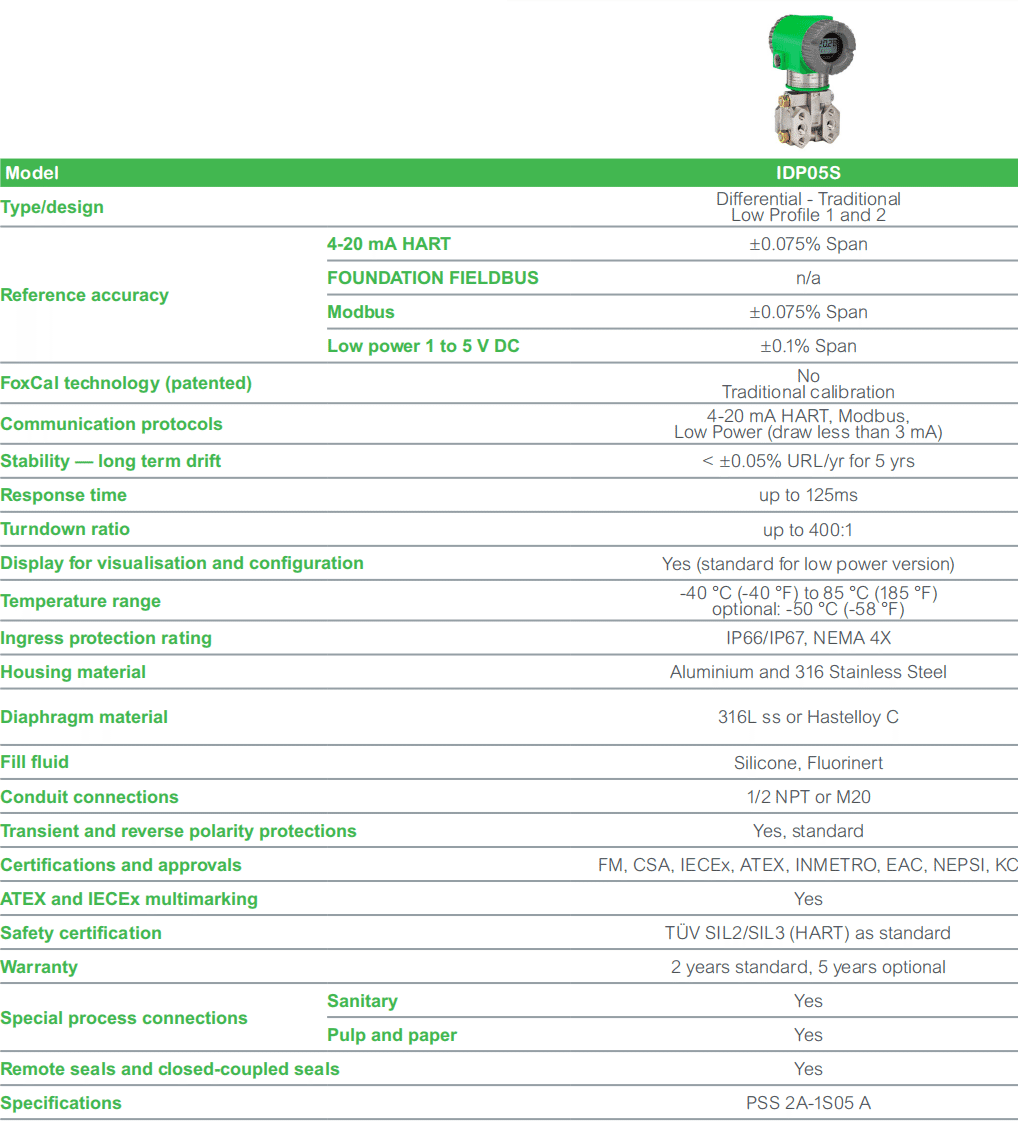

The low-power version of the Value Performance series pressure transmitter runs no more than 3mA and can be installed in remote areas where solar panels or battery-powered electricity is limited. The range accuracy is ±0.075%