★There are no moving parts in the measuring tube, which is easy to maintain and manage; Free flow components, so no pressure loss.

★ The measured liquid conductivity ≥5μs/cm, with a variety of lining materials, can be used to measure a variety of acid, alkali, salt solution and mud, pulp, pulp and other media flow.

★ The measurement of flow is not affected by the change of fluid density, viscosity, temperature, pressure and conductivity, the sensor induced voltage signal is linear with the average flow rate, and the measurement accuracy is high.

★ Reasonable selection of lining and electrode materials can achieve good corrosion resistance and wear resistance.

★ Low frequency rectangular wave excitation, not affected by power frequency and various stray interference on site, stable and reliable work.

★ It is not affected by the direction of the fluid, and can be accurately measured in both positive and negative directions.

★ Range ratio 1:120 (0.1m/s ~ 12m/s), full scale flow rate range is wide.

★ Chinese LCD backlight display, can modify parameters online, easy to operate.

★ With air control measurement, alarm function, and can adapt to different fluid media.

★ Power failure time recording function, automatically record the instrument system power interruption time, make up the leakage flow.

★ Hourly total recording function, record the total flow in hours, suitable for time-sharing measurement system.

|

|

|

Product introduction

Electromagnetic flowmeter in line with the standard KL/T9248-2015 "Electromagnetic flowmeter", is a measurement of conductive medium volume flow induction instrument, in the field monitoring display at the same time, can output standard current signals for recording, regulation, control use, to achieve automatic control of detection, and can realize the signal long-distance transmission. It can be widely used in water, chemical, coal, environmental protection, textile, metallurgy, paper and other industries in the flow measurement of conductive liquid. It has obtained the explosion-proof certificate issued by the National Explosion-proof Electrical Product Quality Inspection Center, and the explosion-proof mark is EXD11CT6, which is suitable for liquid measurement in various explosive environments.

Working principle

According to Faraday's electromagnetic induction principle, a pair of detection electrodes are installed on the wall of the tube perpendicular to the axis of the measuring tube and the magnetic force line. When the conductive liquid moves along the axis of the measuring tube, the conductive liquid cuts the magnetic force line to generate the induced potential, which is detected by the two detection electrodes. The value is directly proportional to the flow rate, and its value is as follows:

E=KBVD

Formula:

E-induced potential;

K- coefficient related to magnetic field distribution and axial length;

B- magnetic induction intensity;

V- average velocity of conductive liquid;

D- electrode spacing; (Measure tube diameter)

The sensor transmits the induced potential E as the flow signal to the converter, which is amplified, transformed and filtered by a series of digital processing, and displays the instantaneous flow and cumulative flow with the dot matrix liquid crystal with backlight. The converter has 4 ~ 20mA output, alarm output and frequency output, and is equipped with RS-485 communication interface, and supports HART and MODBUS protocols.

|

|

Product advantage

1. The electromagnetic flowmeter sensor has a simple structure, no moving parts in the measuring tube, and no throttling parts that hinder fluid flow;

2, can measure the dirty media, corrosive media and suspended turbidity liquid solid two-phase flow flow;

3, during the measurement process, it is not affected by the temperature, viscosity, density and conductivity of the measured medium (in a certain range);

4, the output of the electromagnetic flowmeter is only proportional to the average flow rate of the measured medium, and has nothing to do with the flow state under symmetrical distribution (laminar flow or turbulence);

5, the electromagnetic flowmeter has no mechanical inertia, sensitive response, can measure the instantaneous pulsation flow, but also can measure the flow in both directions;

6, industrial electromagnetic flowmeter diameter selection range is wide.

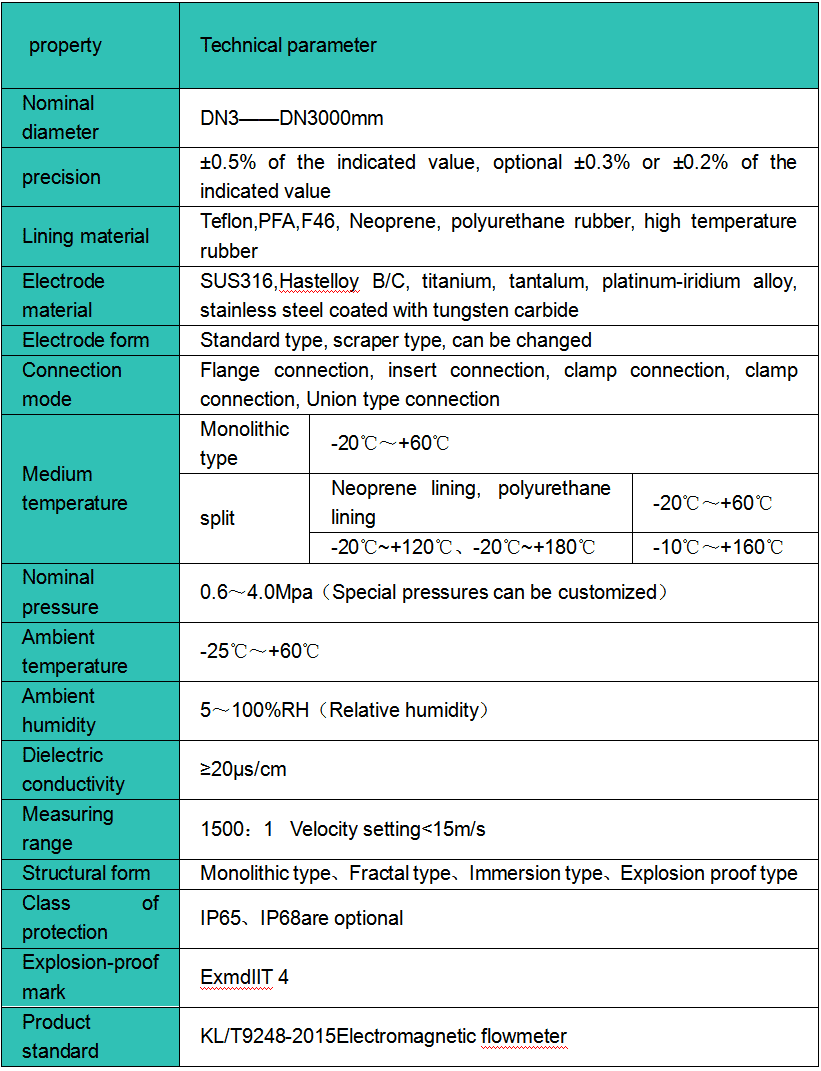

Technical parameter

Application field

Electromagnetic flowmeter is used in: petroleum, chemical, steel, food, power, paper, metallurgy, water supply and drainage, petrochemical, medical and other industries.

Installation precautions

1, no vibration, no strong electromagnetic field (such as large motor, inverter near);

2, as far as possible vertical installation, horizontal installation needs to be installed at a low place, can not be installed pipe apex, to ensure full pipe, prevent bubbles;

3, straight pipe section requirements, ensure the first 10 times after 5 times pipe diameter;

4, welding installation should be careful not to connect the instrument welding, to prevent damage to the flow meter;

5, the shell is grounded as far as possible, the single end of the shielded line is grounded, and the receiving point cannot be common with strong electricity;

6, if for easy maintenance, the installation location needs to be selected to meet the maintenance requirements. At the same time, the side pipe can be installed, and the fluid will go through the side pipe when the fault occurs.

7, avoid direct sunlight, high temperature places, do waterproof, moisture-proof treatment;

8, other requirements should be considered, the signal line should not be with the strong current line.