★The measurement accuracy is not affected by the change of liquid density, viscosity, temperature, pressure and conductivity.

★ High reliability plug-in installation mode, sensor installation, maintenance without disassembling the measuring tube, so it is more suitable for field use can not stop water, and can be installed on the old pipe field opening;

★ Simple structure, electromagnetic flowmeter measuring tube can not be lined, high reliability; The nominal diameter range is wide, suitable for all caliber pipelines between DN100-DN3000;

★ Integrated grounding electrode to achieve good grounding of the instrument; The sensor adopts new processing technology, solid state package, vibration resistance, penetration resistance and long life, so that the instrument has good measurement accuracy and stability.

Product introduction

The working principle of the plug-in electromagnetic flowmeter is based on Faraday's law of electromagnetic induction.

In the electromagnetic flowmeter, the conductive medium in the measuring tube is equivalent to the conductive metal rod in the Faraday test, and the two electromagnetic coils at the upper and lower ends generate a constant magnetic field. When a conductive medium flows through, an induced voltage is generated.

Two electrodes inside the pipe measure the induced voltage generated. The measuring pipe is electrically isolated from the fluid and the measuring electrode by means of a non-conductive lining (rubber, Teflon, etc.).

|

|

Working principle

According to Faraday's electromagnetic induction principle, a pair of detection electrodes are installed on the wall of the tube perpendicular to the axis of the measuring tube and the magnetic force line. When the conductive liquid moves along the axis of the measuring tube, the conductive liquid cuts the magnetic force line to generate the induced potential, which is detected by the two detection electrodes. The value is directly proportional to the flow rate, and its value is as follows:

E=KBVD

Formula:

E-induced potential;

K- coefficient related to magnetic field distribution and axial length;

B- magnetic induction intensity;

V- average velocity of conductive liquid;

D- electrode spacing; (Measure tube diameter)

The sensor transmits the induced potential E as the flow signal to the converter, which is amplified, transformed and filtered by a series of digital processing, and displays the instantaneous flow and cumulative flow with the dot matrix liquid crystal with backlight. The converter has 4 ~ 20mA output, alarm output and frequency output, and is equipped with RS-485 communication interface, and supports HART and MODBUS protocols.

|

|

Product advantage

1, The electromagnetic flowmeter sensor has a simple structure, no moving parts in the measuring tube, and no throttling parts that hinder fluid flow;

2, can measure the dirty media, corrosive media and suspended turbidity liquid solid two-phase flow flow;

3, during the measurement process, it is not affected by the temperature, viscosity, density and conductivity of the measured medium (in a certain range);

4, the output of the electromagnetic flowmeter is only proportional to the average flow rate of the measured medium, and has nothing to do with the flow state under symmetrical distribution (laminar flow or turbulence);

5, the electromagnetic flowmeter has no mechanical inertia, sensitive response, can measure the instantaneous pulsation flow, but also can measure the flow in both directions;

6, industrial electromagnetic flowmeter diameter selection range is wide.

|

|

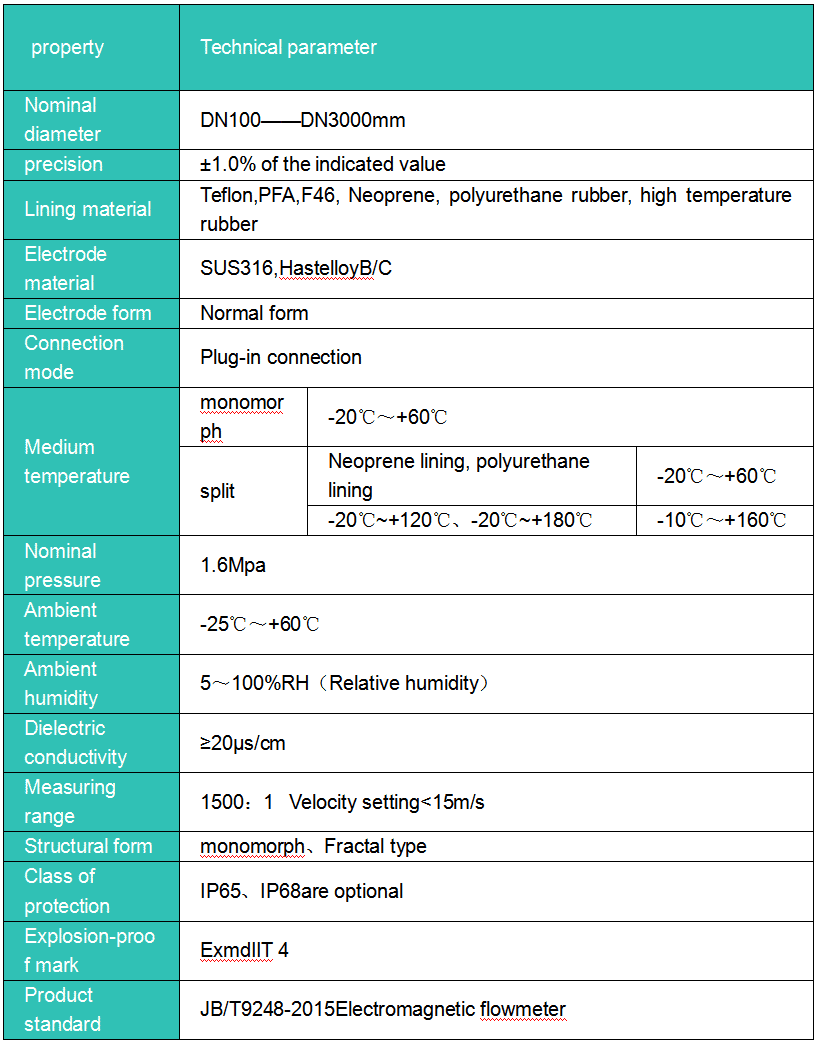

Technical parameter

Application field

Electromagnetic flowmeter is used in: petroleum, chemical, steel, food, power, paper, metallurgy, water supply and drainage, petrochemical, medical and other industries.