Product introduction

KL series metal tube float flowmeter is a flowmeter manufactured according to JB/T6844-93 industry standard.

It uses the dynamic action of the fluid to make the float move upward along the flow in the vertically installed measuring tube, and the displacement of the float is proportional to the size of the flow rate. Through the magnetic transfer system, in a non-contact way, the float displacement is passed to the indicator directly indicating the size of the flow rate.

The meter smart card in accordance with HART communication protocol is installed in the indicator, and the user can use HART communication software or hand operator to manage and adjust the instrument and monitor process variables during operation.

The FBLZ flowmeter has the advantages of simple structure, convenient maintenance, reliable operation and wide applicability, and can be used to measure the flow of liquid, gas and steam.

|

|

Performance characteristics

1, the safety explosion-proof, flameproof design, large screen LCD display, can simultaneously display instantaneous flow and cumulative flow. Wide temperature liquid crystal display, can meet the harsh working environment,

Ambient temperature :-25 ~ +75℃

The upper row shows instantaneous flow, and the lower row shows cumulative flow. Instantaneous flow display range :0.00 ~ 9999.99;

Cumulative traffic display range :0.00 ~ 999999.90; Current display range :2.86 ~ 21.00mA;

Pointer Angle display range :0.00 ~ 90.00°; Ambient temperature display range :-50 ~ +150℃;

The cumulative small signal removal range :0.00 ~ 1.00(equivalent to 0 ~ 100%).

2, the upper row can be switched to display: instantaneous flow, loop current, cumulative small signal cutting amount, current ambient temperature, pointer rotation Angle and other information. In this case, the display of the cumulative quantity in the bottom row is not affected

3, instantaneous flow and cumulative flow units can be set at will

The scale flow of the panel, the instantaneous flow of the liquid crystal display, and the cumulative flow of the liquid crystal display can be set to different units. For example: the panel scale is set to L/h, while the liquid crystal display instantaneous flow unit can be set to m3/h, the cumulative quantity can be set to L, m3, etc., and the cumulative quantity unit can be set to tons or kilograms according to the density determined when ordering. Flexible Settings to meet the various needs of customers.

4, the liquid crystal can display the instantaneous flow under the second working condition, when ordering, the cumulative amount can choose the cumulative amount under the first working condition or the cumulative amount under the second working condition. Due to changes in operating conditions, the displayed flow range can be modified online in the field.

When in field use, due to changes in working conditions (such as changes in working pressure, medium density, etc.), it is necessary to adjust the flow range. Just according to the operation of the instruction manual, after calculation, adjust the flow coefficient and time coefficient. In this case, the traffic indicated by the pointer can be ignored. The tedious return to the original factory re-calibration is eliminated. This can better adapt to complex field situations.

5, perfect power failure protection function. In case of power failure, the current accumulated traffic can be saved (the cumulative volume sampling period is 0.3S), and the advanced six-level data backup mechanism is adopted, so that the loss of data may be minimal.

|

|

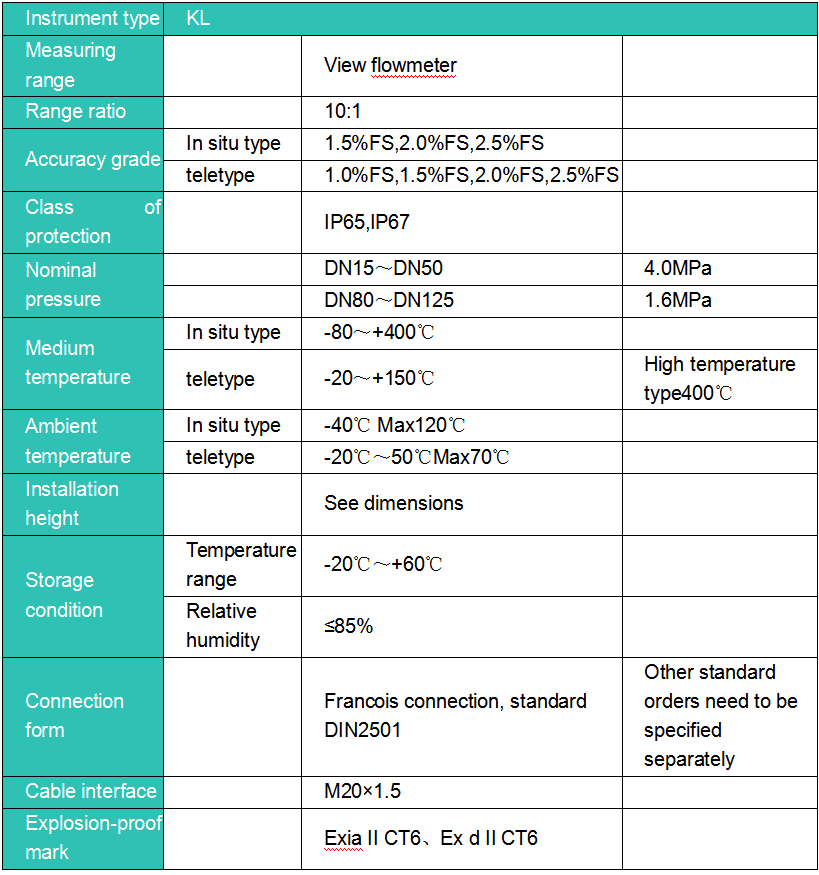

Technical parameter