Brief introduction of advantages

We use superior Schneider Electric technology and experience to measure the level, interface or density of fluids in industrial processes over time. Based on the tried-and-tested Archimedes principle of buoyancy, without any moving parts our level transmitters are robust, extremely reliable and virtually maintenance-free.

They provide accurate measurements even at extreme process temperatures from -196 ° C to +500 ° C (-320 ° C to +930 ° C) and pressures from vacuum to 500 bar.

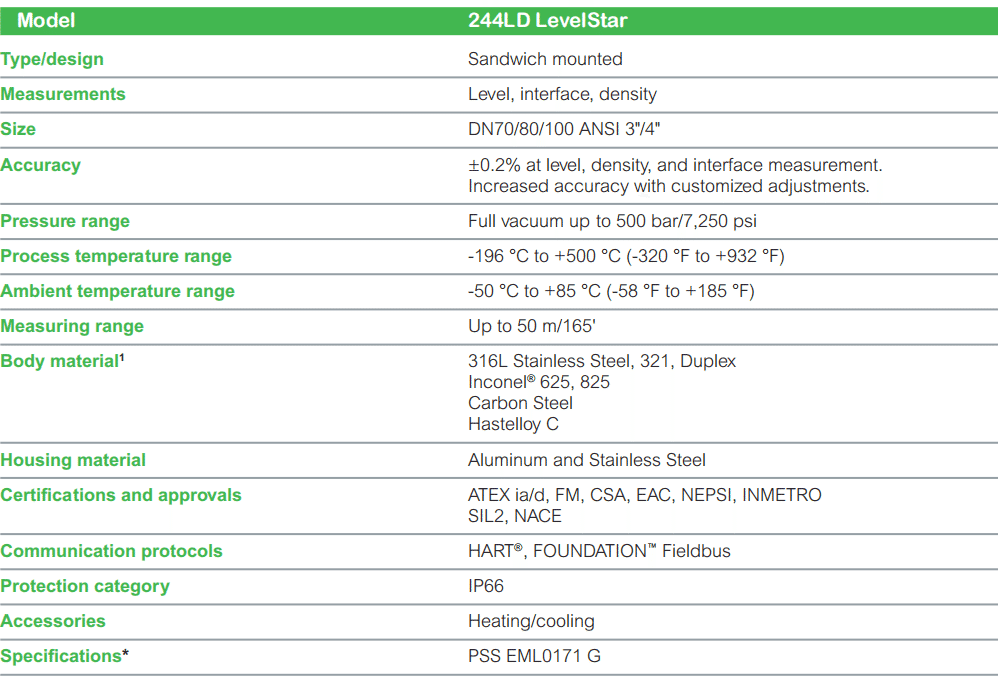

Our loop powered float transmitters provide HART® and FOUNDATION™ fieldbus communication. LCD display and buttons make calibration and adjustment a breeze. They use process liquid materials such as carbon steel, stainless steel, Inconel, Duplex and Hastelloy C. Designed to withstand challenging process environments, the 244LD has ATEX, FM, CSA, EAC, NEPSI and INMETRO prescribed grades, as well as explosionproof and intrinsic safety options. In addition, the float instrument has been approved for SIL2 safety applications with verification test intervals of up to five years.

Selection guide

244LD LevelStar Buoy Transmitter is the flagship product of the buoy transmitter family. Rugged design for extreme process temperatures makes it the first choice for liquid level measurement in all industrial processes.

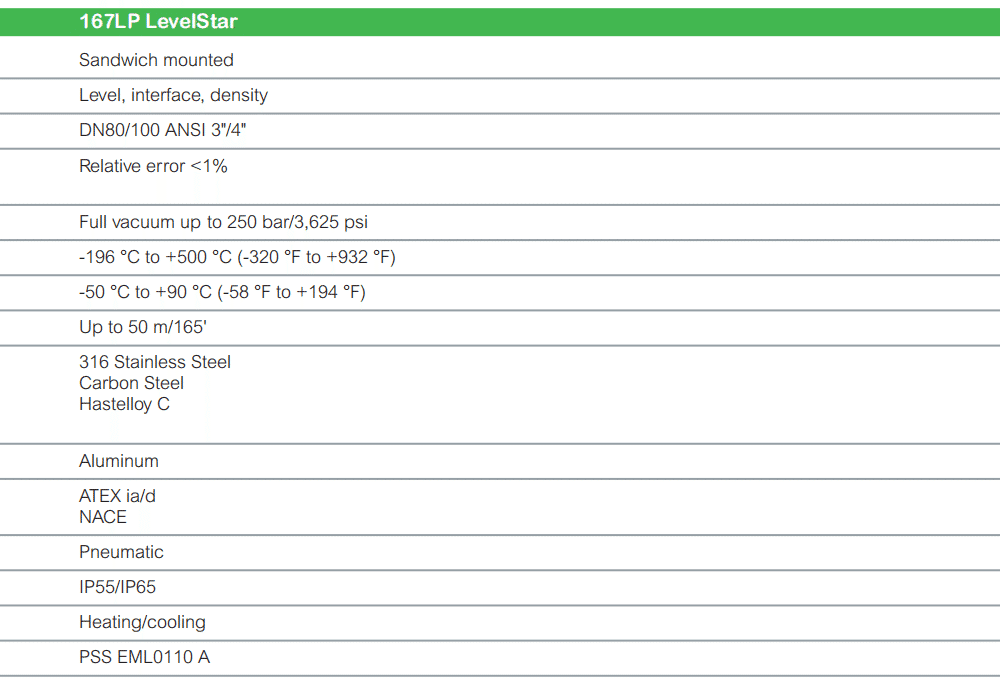

The 167LP pneumatic transmitter is used to measure liquid level, interface or density. The transmitter converts the lifting force of the buoy body into a pneumatic output. It is ideal for extreme process level measurement.