Brief introduction of advantages

Schneider Electric's 84 ° C series intelligent vortex flowmeters have proven to be the perfect choice for the many accuracy, reliability and cost challenges that can arise in a process.

There is no need to specify various models for fluid, gas, and vapor measurements. With Schneider Electric Vortex flow meters, a single sensor design can meet most measurement needs. Moreover, the 84C Series vortex flowmeters provide built-in temperature compensation options for saturated steam or medium specific mass flow metering, and with the introduction of the series, it will provide a higher value solution to meet your measurement needs. As a result, you can easily order, reduce inventory, and reduce overall costs. Even after years of long-term use, you get predictable and accurate performance for a long time at a very low cost of ownership.

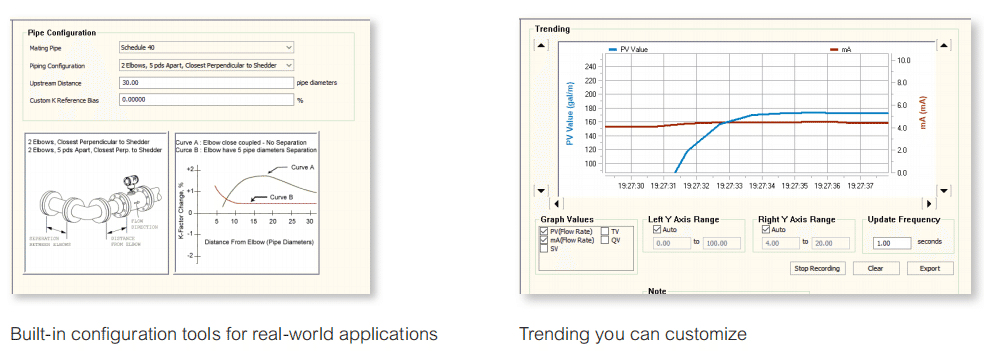

The 84C series can be used for Modbus RTU or HART7 communication, and Modbus is implemented over a 2-wire RS-485 multipoint serial connection, which frees up more cabinet space and runs faster than HART. Its explosion-proof and fire-proof electrical certifications make it ideal for use as upstream equipment in the chemical and oil and gas industries. The Modbus DTM comes with a simple 7-step configuration wizard that gets you up and running in 2 minutes.

Smart and durable design

The shape of the vortex generator is unique and does not require moving parts, so there is no loss or loss of accuracy. The 84C optional built-in Pt1000 RTD temperature sensor provides best-in-class accuracy to compensate the mass flow of saturated steam.

The patented "DirectSense™" vortex street sensor puts the sensor in the right position to perfectly act on the process, resulting in a large range and excellent low flow performance. Like the robust epoxy-coated housing, the ruggedized sensor (backed by a lifetime warranty) can withstand the rigors of the process. An optional isolation valve bank allows you to replace the entire sensor assembly without shutting down the process and maintain process pressure and temperature conditions.

Intelligent model

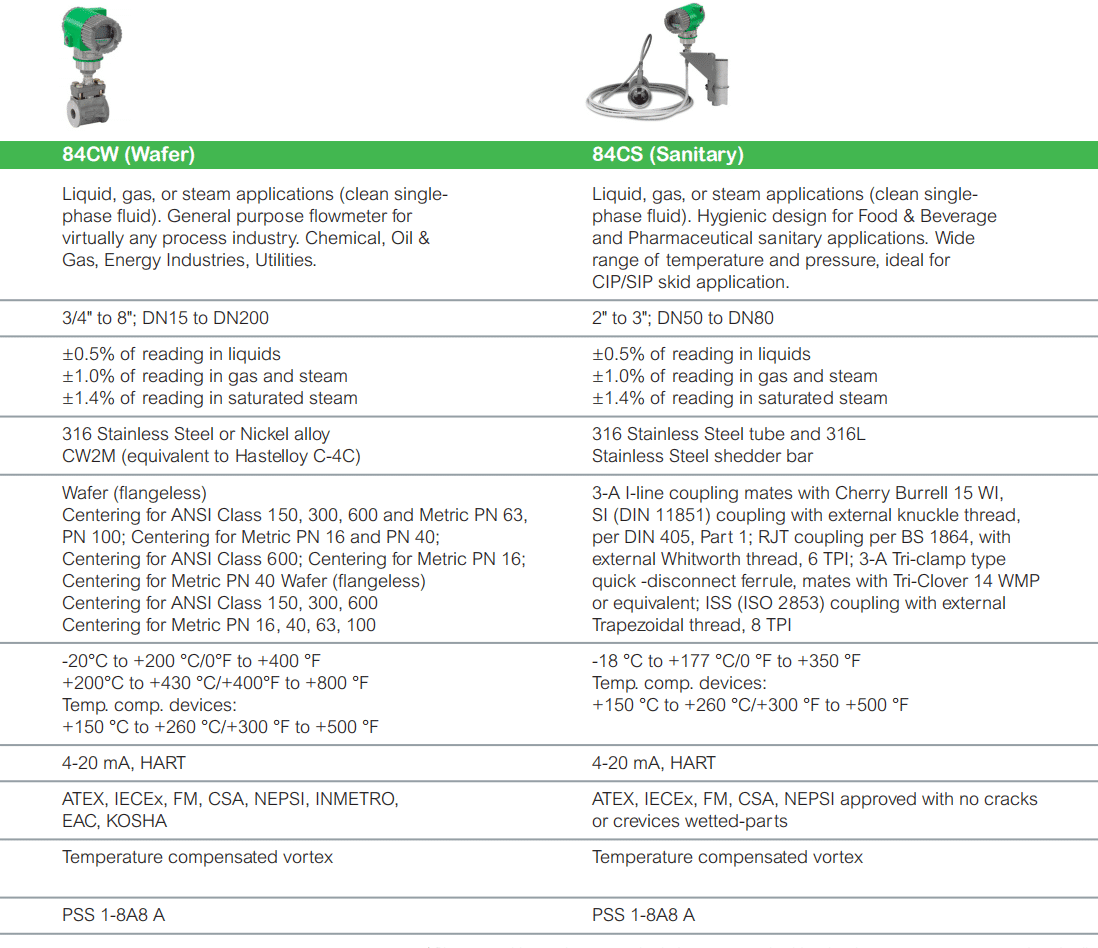

Schneider Electric's smart vortex flowmeters offer exceptional low flow characteristics, wide range ratios and in-line diagnostics. They also include K-factor correction for temperature effects and compensation for pipe effects to provide the most accurate measurements possible.

As with many Schneider Electric meters, you can query or configure them remotely by selecting PC software based on the FDTDTM standard or any handheld terminal using DD files.

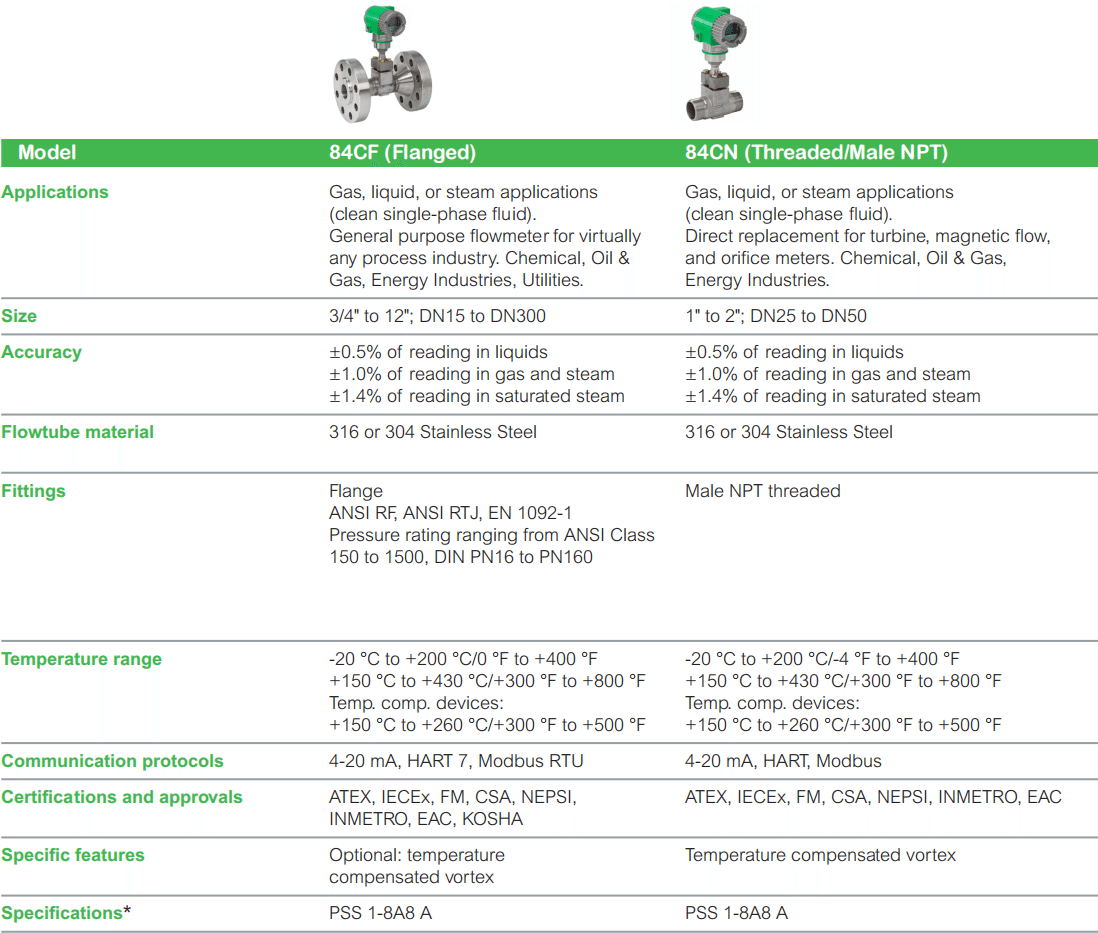

Version selection

Flange and clamped vortex flowmeters can measure fluids, gases, or steam at process temperatures up to 430 ° C (800 ° F).

The Sanitary Smart Vortex flowmeter is the only 3A certified sanitary vortex flowmeter in the industry and is authorized for applications that require a seamless design for in-line cleaning.

The 84CS sanitary Vortex flowmeter is suitable for sanitary applications and CIP cycles.

With temperature compensation, the 84C vortex flowmeter reduces operating costs and is an excellent solution for measuring the mass flow of saturated steam or specific media.

Selection guide