Brief introduction of advantages

Schneider Electric's mass flow meters cover a full range of models to meet your application needs. Our Coriolis flowmeter range is available in a variety of sizes for high pressure, low temperature and high temperature applications. The instrument's diagnostic software monitors a range of process values and auxiliary values to conclusively confirm the condition of the process media. When bubbles or solids exceed a certain percentage, our Coriolis mass flowmeters can even generate intelligent warning messages that provide valuable information about the process itself.

When constant parameters such as media, temperature or pressure change dramatically, a reliable and accurate mass flowmeter is required. Schneider Electric offers superior mass flow meters with a unique straight tube design for minimal pressure drop for high viscosity, high corrosion and slurry applications. Whatever your process needs, you can get the design and quality you need with Coriolis mass flow meters from Schneider Electric.

Typical application:

Measure fluids, gases, and fluids with gases

In bulk

Chemical oil gas

Food and beverage

Chemical engineering

pharmacy

petrification

Power station

Pulp and paper making

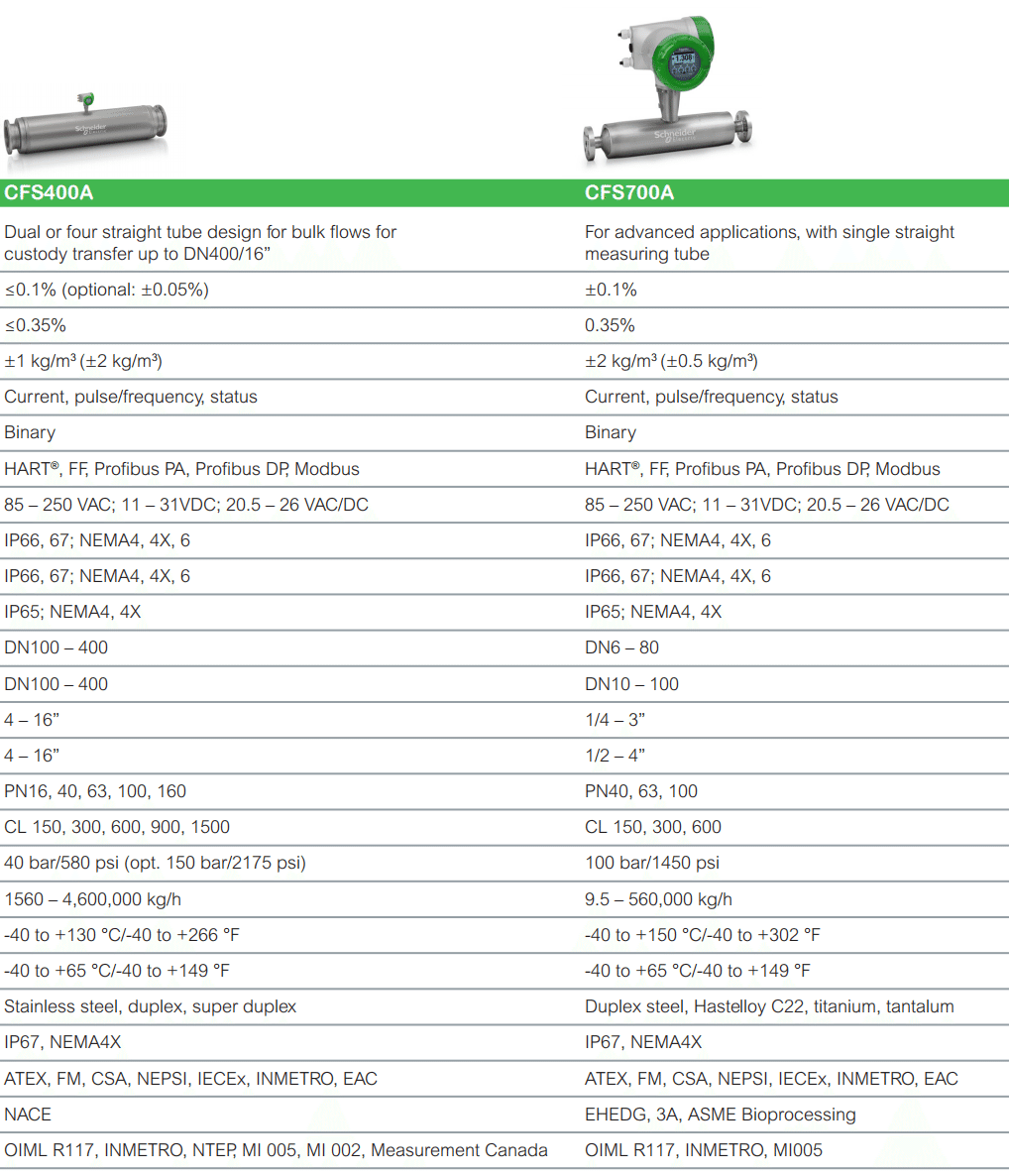

If the total pressure drop of the installed flow meter is high, greater energy consumption will be generated, resulting in increased investment costs to install more powerful pumps. Importantly, for offshore and Marine markets, the greater the weight of these more powerful pumps, the greater the weight added to the platform or vessel. To reduce the pressure drop of the overall system, the right flowmeter can play a vital role in achieving this goal. Our CFS400A features a unique four-straight tube design with an optimized shunt for producing low pressure drops. It also has extremely high flow rates of up to 4,600 tons per hour, or 169,000 pounds per minute.

Powerful transmitter for standard and challenging applications

The CFT34A is an electronic device ideal for all high-tech metering tasks. When entrainment gas is present, its technical strength is demonstrated, and continuous measurements can be made at 0% to 100% gas entrainment and reverse entrainment. The CFT34A also offers excellent high level density determination at zero levels. The CFT34A is compatible with CFS300A, CFS400A, CFS600A, and CFS700A Coriolis flow tubes and comes standard with buttons and optical keys. The transmitter is certified by CFMUS, ATEX, IECEX, EAC, NEPSI and INMETRO. Its compact remote installation design with advanced measurement capabilities provides superior density determination capabilities. Advanced diagnostic capabilities for situational monitoring and robust design make it an important measurement tool that is not affected by gas entrainment. When an electronic device fails, the entire electronic device module can be quickly replaced on site. Allowing for redundant storage, data can be easily transferred from the backplane memory of the housing to the new transmitter, so the whole process is only interrupted briefly.

Repeatable two-phase flow metering

If the mass flow meter measurement is interrupted due to the entrainment of gas in the medium, consider switching to the Coriolis mass flow meter from Schneider Electric. Whether you have excess entrain gas in your process or need air inside your product, Schneider Electric's Coriolis mass flow meters ensure stable and continuous operation in a wide range of gas fractions and complex flow conditions.

Schneider Electric's two-phase flow capability provides solutions for flow conditions with a gas volume fraction (GVF) ranging from 0 to 100% :

The application problem of entrainment gas can be easily solved

Enhanced diagnosis with two confidence numbers

The diagnosis met the requirements of NAMUR NE 107

Continuous measurement of entrainment from 0 to 100%

Working principle

The regular oscillation of the tube in Coriolis mass flowmeter is an ideal state. The entrain of air in the fluid will weaken this regular oscillation of the flow metering tube. As the air content increases, the oscillation may stop completely. This problem can be overcome with powerful control algorithms that allow the meter to oscillate and continuously measure even during the full transition from 100% liquid to 100% gas phase - as is the case with the Coriolis mass flowmeter from Schneider Electric.

Coriolis flowmeters can measure the mass flow and density of any fluid, whether it contains air or not. Density and temperature measurement of single-phase fluids (i.e. no entrainment of air) is a common practice, but entrainment of gases can be challenging for conventional mass flowmeters. In many applications where entraining gases are present, Schneider Electric's Coriolis mass flowmeters demonstrate excellent accuracy and repeatability in process control, dosing, loading, unloading and handover measurements.

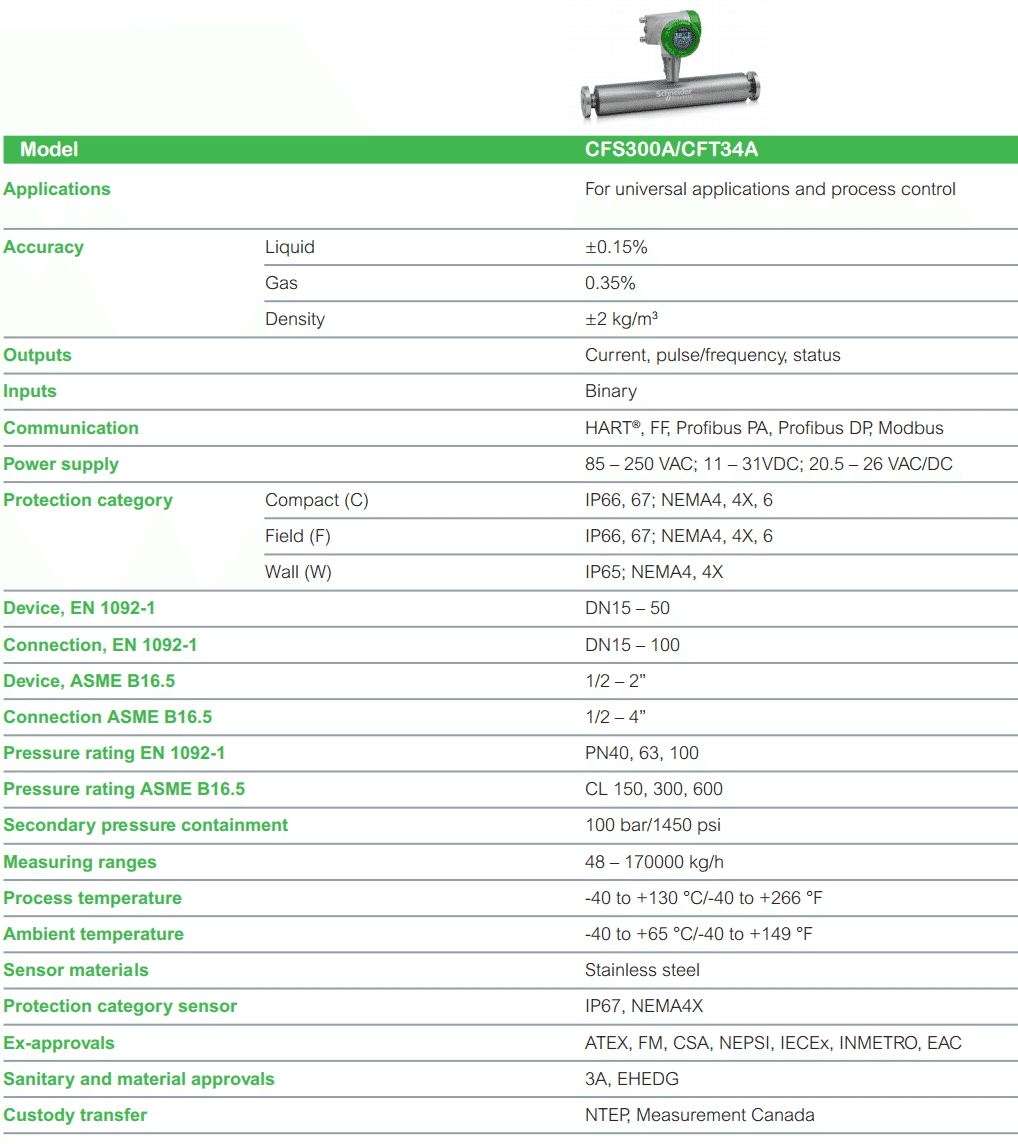

Selection guide