Clamp connected vortex flowmeter overcomes the general flowmeter joint needs to evenly spread bolt holes on the connecting disc, the use of bolts, nuts to fix the connecting disc on the pipeline, resulting in high cost, trouble in operation, low efficiency, and change the use of cross section of the right trapezoid connection disc, the inside of the right trapezoid bevel, in use, the use of clamps to fasten the connecting disc on the pipeline. Low use cost, save time and effort. Clamp flowmeter is mainly used in oil fields and other high complexity of the work.

Product introduction

Clamp connected vortex flowmeter overcomes the general flowmeter joint needs to evenly spread bolt holes on the connecting disc, the use of bolts, nuts to fix the connecting disc on the pipeline, resulting in high cost, trouble in operation, low efficiency, and change the use of cross section of the right trapezoid connection disc, the inside of the right trapezoid bevel, in use, the use of clamps to fasten the connecting disc on the pipeline. Low use cost, save time and effort. Clamp flowmeter is mainly used in oil fields and other high complexity of the work.

|

|

Product advantage

Clamp connected vortex flowmeter adopts a connection disk with a right Angle trapezoid cross section, and the bevel of a right Angle trapezoid is relative to the inner side of the cross section. When used, the connection disk is fastened to the pipeline with a clamp, saving time and labor. In addition, a stuffing box is arranged on the connecting interface between the connecting disk and the pipeline, which has good sealing performance, high sealing strength and convenient use.

|

|

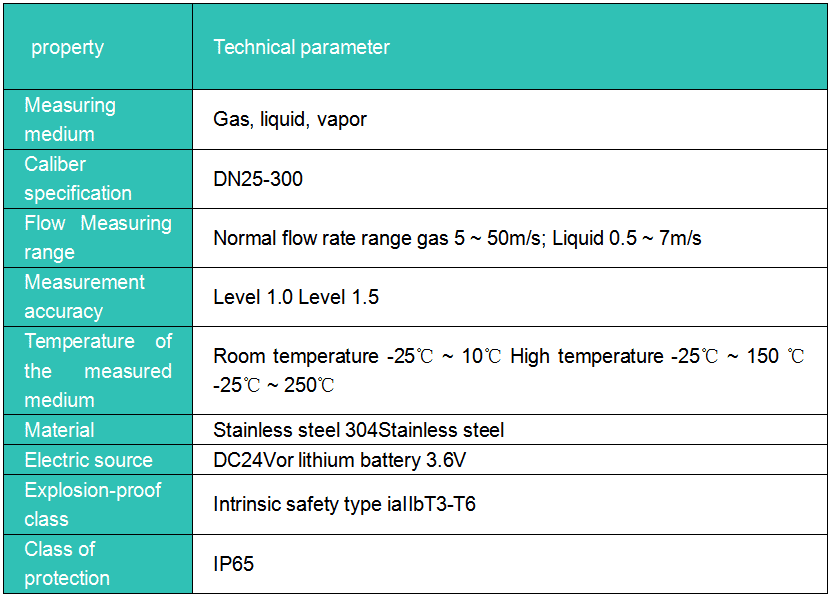

Technical parameter

How to select products

The correct type selection can ensure the better use of the clamp-connected vortex flowmeter. What kind of vortex flowmeter should be selected should be determined according to the physical and chemical properties of the measured body medium, so that the diameter, flow range, lining material, electrode material and output current of the vortex flowmeter can adapt to the properties of the measured body and the requirements of flow measurement.

01. Precision functional check

Accuracy level and function According to the measurement requirements and the use of the instrument accuracy level, to achieve economic. For example, for trade settlement, product handover and energy measurement, the accuracy level should be higher, such as 1.0, 0.5, or higher; For process control, different precision levels are selected according to control requirements; Some are just to detect the process flow, do not need to do control and measurement occasions, you can choose a slightly lower accuracy level, such as 1.5, 2.5, or even 4.0, then you can choose a low-cost plug-in vortex flowmeter.

02. Measurable media

When measuring medium flow rate, instrument range and aperture measurement of general media, the full degree flow rate of the vortex flowmeter can be selected in the range of measuring medium flow rate 0.5-12m /s, and the range is relatively wide. The selection of instrument specifications (caliber) is not the same as the process pipeline, should be determined according to whether the measured flow range is within the flow rate range, that is, when the pipeline flow rate is low, can not meet the requirements of the flow meter or the measurement accuracy cannot be guaranteed at this flow rate, it is necessary to narrow the instrument caliber, so as to increase the flow rate in the tube, and obtain satisfactory measurement results.

|

|

03. Selection of vortex flow transmitter

The VA type piezoelectric vortex flow transmitter is used in the saturated steam measurement. Due to the wide range of the vortex flow meter, in practical applications, the main consideration is that the flow rate of saturated steam measured should not be lower than the lower limit of the vortex flow meter, that is to say, the fluid flow rate must not be less than 5m/s. According to the size of the amount of steam used, vortex flow transmitters of different calibers can be selected, rather than the existing process pipe calibers.

04. Pressure compensation pressure transmitter selection

Since the saturated steam pipeline is long and the pressure fluctuation is large, pressure compensation must be used. Taking into account the corresponding relationship between pressure, temperature and density, only pressure compensation can be used in the measurement. Because the saturated steam pressure of the pipeline is in the range of 0.3-0.7MPa, the measuring range of the pressure transmitter can be selected as 1MPa.

05. Display instrument selection

Display instrument Intelligent flow display instrument, with voltage compensation, instantaneous flow display and cumulative flow integration functions.

Application field

The clamp connected vortex flowmeter is used in the process measurement and energy saving management of various low-viscosity liquid, gas, steam and other single-phase fluids in petroleum, chemical industry, metallurgy, machinery, paper making, and urban pipeline heating, water supply, gas and other industries.