Product introduction

LUGB flange clamped vortex flowmeter is a commonly used structure, its body itself does not have a connection flange, in connection with the pipe, the flowmeter clamped between two special flanges, and then bolted. It is characterized by small size and simple and compact structure. At the same time, special flanges and fastening bolts are provided, so the installation cost is low and the installation is very convenient.

|

|

Product advantage

Easy to install and easy to maintain;

Simple and firm structure, no moving parts, long-term operation is very reliable;

Wide range, range ratio up to 1:15;

Small pressure loss, low operating cost, more energy saving significance;

Wide range of applications, liquid, gas, steam can be measured;

The verification cycle is long, generally two years;

In a certain range of Reynolds number, the output signal is not affected by the change of physical properties and components of the measured medium, the instrument coefficient is only related to the shape and size of the vortex generator, and it is generally not necessary to re-calibrate the instrument coefficient after replacing the parts.

It can be displayed on the spot, can also be transmitted remotely, and can also be networked with the computer control system;

The detection probe does not directly contact the measured medium, and the performance is more stable.

|

|

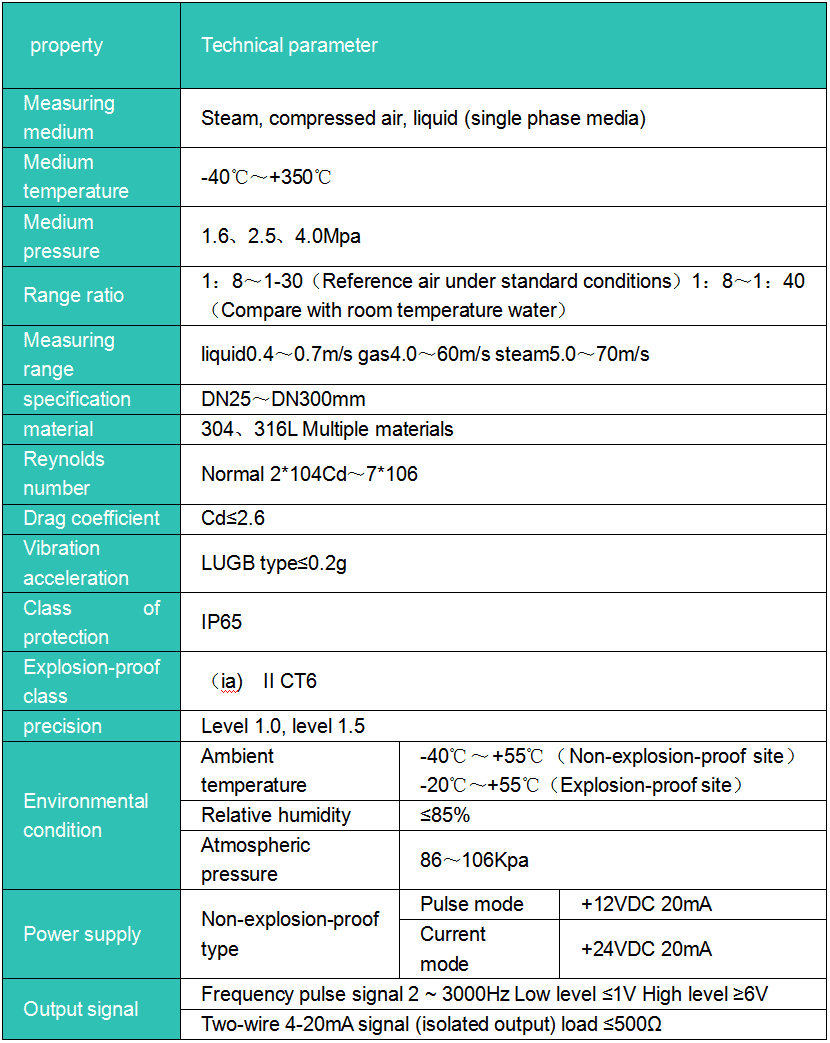

Technical parameter

How to select products

The selection of vortex flowmeter mainly confirms the following parameter requirements:

01. Measure the medium

Vortex flowmeter is a kind of velocity flowmeter, which uses the principle of Karman vortex street, when the medium passes through the vortex, it will form a small vortex in the back, and the number of vortices can be converted into the flow rate of the medium, and then into the flow rate of the medium. Its principle determines its type of measurement medium, which can be liquid, gas or steam. At present, the vast majority of industrial occasions, such as nitrogen, compressed air, steam, thermal oil, etc., are mostly measured by vortex flowmeters.

02. Pipe caliber

Vortex flowmeters can be divided into pipeline and plug-in installation according to the different installation methods. For the pipeline type, the pipe diameter is the same as most other flowmeters, the small is DN15, and the large is able to reach DN300. If you need a larger caliber, you can choose to insert the installation, the conventional caliber range can reach DN2000, DN2000 caliber is supplied in accordance with the agreement.

03. Measurement accuracy

The accuracy of the vortex flowmeter also has several grades, and it is divided according to the measurement medium. If it is to measure liquid, the measurement accuracy can reach 1.0, and if it is to measure gas, the accuracy can reach 1.5. If it is a plug-in vortex flowmeter, the accuracy can reach 1.5 and 2.5 levels.

|

|

04. Medium temperature

Generally speaking, it is divided into three ranges, which are divided into normal temperature, moderate and high temperature. The temperature range is -40 ~ 100℃(normal temperature), 100 ~ 250℃(medium temperature), 100 ~ 320℃(high temperature). If the field medium temperature is higher, such as some superheated steam, you can use the orifice flowmeter to measure.

05. Nominal stress

Mainly according to the installation method, the main demand on the market is as follows: for example, flange clamp type (2.5MPa), flange connection type (1.0/1.6/2.5MPa), plug-in installation type (1.6MPa/2.5MPa/4.0MPa).

06. Power supply

According to the current market demand, there are mainly +12VDC(three-wire pulse output), +24VDC(three-wire pulse output type and two-wire current output type)3.6V lithium battery, dual power supply.

07. Output signal

According to the current market demand, there are mainly voltage frequency pulse output, two-wire 4-20mA output and HART output. In addition, some occasions may require digital output, we can also provide modbus RS485 communication.

Application field

The clamped vortex flowmeter is used in process measurement and energy saving management of various low-viscosity liquids, gases, steam and other single-phase fluids in petroleum, chemical industry, metallurgy, machinery, food, paper making, and urban pipeline heating, water supply, gas and other industries.